Robotics in the Fast Casual Sector

July 31, 2024

For many, the last day of July marks the middle of the endless summer. Beach, barbeques, bocce ball… anything is possible. As far as Chipotle is concerned, however, July 31st is National Avocado Day and that means guacamole, and lots of it. It takes one of their experienced workers about a minute to cut, core and peel each avocado, a seemingly insignificant detail until one considers that a typical location goes through about 180 of them a day. Over the course of a year, that’s 65,000 avocados. Multiply that across 3,200+ locations, that’s 200 million avocados, each requiring that same minute of labor. A novel way to reduce that minute may be sitting in a lab in Irvine, California. About the size and shape of an undercounter refrigerator, Autocado is a cobot, or collaborative robot, that can prepare the fruit (yes it is a fruit) in about half the time a person can. It’s just one of the many cobots ready to enter, or have already entered, the fast casual kitchen.

Robotics have long been a part of the food industry. Usually operating from the factory floor or industrial kitchen, they have been packaging and preparing food stuffs for half a century. By taking over simple, repetitive tasks, industrial robots have been able to improve the consistency, reliability and supply of restaurant products while reducing their costs. Cobots differ from them in that they are designed to safely interact with people in a shared workspace. Over the past decade, advancements have made them small and nimble enough to operate within a restaurant’s kitchen, responding to needs in real time.

It’s not hard to imagine the potential benefits. Automating repetitive tasks can allow workers to focus more on people driven tasks, in particularly customer service. Cobots can gauge cooking time and temperatures with near perfect accuracy, streamlining kitchen speed and capacity. Their ability to precisely measure ingredients and weights allow for greater product consistency while reducing food waste. They can take on undesirable or dangerous tasks, resulting in fewer accidents and less downtime. If properly maintained, they can improve food hygiene. So given the benefits, what is preventing them from completely taking over the fast casual kitchen? As with anything else, do the benefits outweigh the costs?

While the potential to reduce labor costs is immense, it’s not infinite. Cobots are designed to work alongside, not replace, us upright primates. First, while cobots don’t get sick, they can break down, so skilled workers will be needed to service them. Second, even with optimistic allowances for the foreseeable future, cobots cannot perform many restaurant tasks, especially those that require dexterity and intuition. Third, collaborative robots need people to help them complete tasks. Though Autocado can prepare avocados by the case, that case still needs to be loaded (in a specific, vertical order) and unloaded by people. The same holds for cobots already in commercial service. Miso Robotics’ Flippy might be able to cook up White Castle french fries 30% faster than people can, but workers must fill its hoppers and change the oil. Picnic Work’s Leonardo can crank out a fully loaded pizza every 27 seconds but needs workers to refill the ingredients and put the pizza in the oven.

The utility of a cobot is commensurate with the labor it can replace. Cobots are generally task oriented, meaning they are designed to perform a specific task. Eateries with compact, focused menus have a greater potential for that task to represent a substantial portion of a kitchen’s output: a burger shop might generate 2/3’s of its revenue via burgers and fries. One fast casual that meets this task concentration is Sweetgreens. Most of its food revenue comes from salad bowls and protein plates, so its Infinite Kitchen, a cobot that assembles its bowls and plates from purchase to presentation, might justify its half million dollar price tag.

Fast casuals with wider menus may require a more strategic approach. Though Chili’s sports a large, diverse menu, it determined that it moved enough steaks and smash burgers to pilot Garland’s $42,000 Xpress Grill, a double-sided grill that can cook meat three times faster than humans can. Not only does this increase kitchen capacity and allow workers to concentrate on other tasks, but its AI powered temperature control self-manages proper cooking consistency. Given Chili’s comps about 6 million dollars worth of steaks every year due to incorrect temperature, that’s a lot of customer satisfaction and revenue at stake. (pun intended!)

Even when cobots have these task concentrations, fast casual brands with fresh, healthy ingredients can be slow to adopt, as they don’t always lend themselves to automation. Picnic Work’s Leonardo has no problem adding diced peppers or pepperoni to its pizzas, but some toppings, like (shudder) pineapple, must be spread by hand. Advances in robotics might solve such hiccups, making it more attractive to restaurateurs and investors, though advancements can take a while. Despite Infinite Kitchen’s ability to mix 50 different ingredients into its salads, goat cheese was only recently added, having stumped its designers for two years.

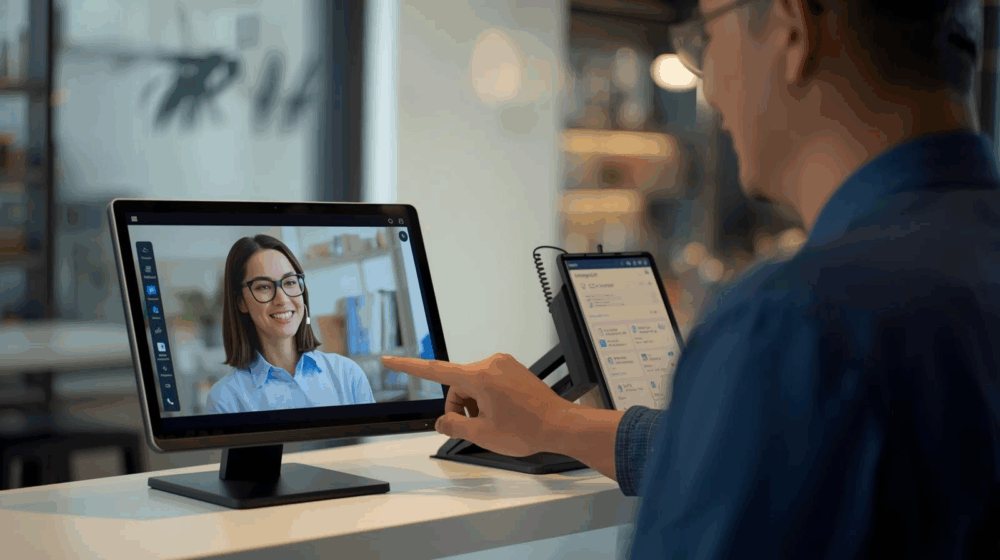

The role of cobots in the fast casual sector will continue to grow as improvements make them more able and affordable. Every Smart Kitchen Summit (this year in Seattle) heralds a steady progression of robotic penetration into the consumer meal. How far it can go is only limited by guest expectations. While fast food guests would likely accept a fully automated experience, especially if it could reduce waiting times and prices, fast casual customers have different priorities. They seek personalized experiences and positive interactions with staff, particularly when ordering and receiving their food. Though a majority of fast casual guests were fine with cobots cooking and cleaning in the kitchen, they are not as thrilled directly interacting with them. Naturally, this impacts ordering kiosks. Compared to fast food, adoption is lagging in fast casual, though Panera was one of the first adopters. This, however, may change with time. Only 39% of baby boomers are comfortable ordering through kiosks, while 62% of millennials are hip so as population changes, so may attitudes.

It’s fitting to wrap up on the concern that cobots may be too good at their jobs. Dishes which are too perfectly portioned and too uniformly cut can remind guests of processed food. Creator —the cobot of the same named San Franciscan restaurant which has since folded— cooked and customized burgers from start to finish, only needing humans to restock ingredients. To give its burgers more character, it was designed to cut its buns with slight inconsistencies. Competing pizza making cobots employ different ways to apply sauce to the dough, all trying to recreate that tasty yet irregular feel of handmade pizzas. Chippy, Chipotle’s tortilla making cobot, is programmed to make them with imperfections. Sometimes the best way to keep the human touch is to just keep the humans. Despite the investment the brand has made in Autocado, it has no plans to automate the hand mashing of the avocados into guacamole: the inevitable imperfections are too precious to lose, because who doesn’t love finding that odd little lump of avocado in their guac?

Leave a Reply